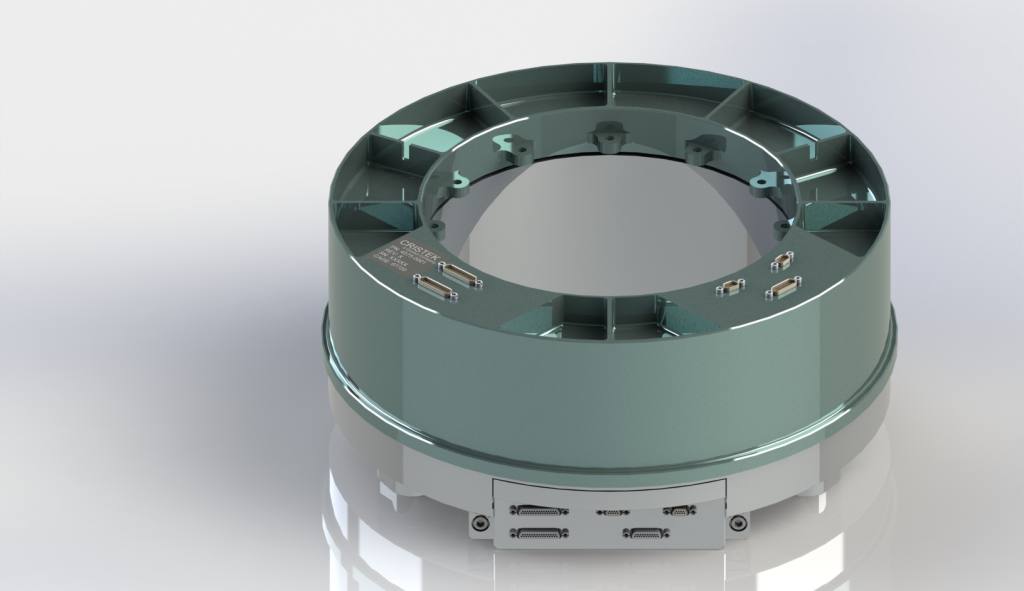

Cristek Twist Capsule

Leveraging their high-density connector design, harness and flex assembly development, and precision machining expertise, Cristek’s emerging product line is primed for significant future investment and growth.

The twist capsule is an application specific design which combines structural components (stator and rotor) with a stable and firm interconnect construction throughout (connectors, cable, flex circuitry, etc.).

The assembly provides up to a total rotation of 360 degrees (175 degrees in either direction). This packaging approach yields a higher life expectancy and substantially lower torque than a traditional cable assembly. Twist capsules can provide higher circuit density and are typically more cost effective than a slip ring. They also beat the slip ring solution by providing higher signal quality over the system life and having the best overall torque and stability performance.

Cristek’s expertise in high density connector design (down to .025” pitch), harness and flex assembly development and precision machining are laying the foundation for this emerging product line to become a major focus for future investment and growth. Due to the critical need for cleanliness and FOD control to optimize twist capsule performance, assembly is performed in Cristek’s “control room.” Twist capsule for the rotating interface offers numerous benefits, such as:

Orion Series™

Hydra Series™ Signal and Power: Commercial / Space

Aquila Series™ High Frequency and Transmission: Space Applications

If you want to learn more about Cristek Twisted Caps please contact us.

Download Twist Capsule Whitepaper.